Gas Storage Hot Water Systems{Resource Guide} Perth Plumbing 2018

Gas Storage hot water system{Resource Guide} Perth 2018

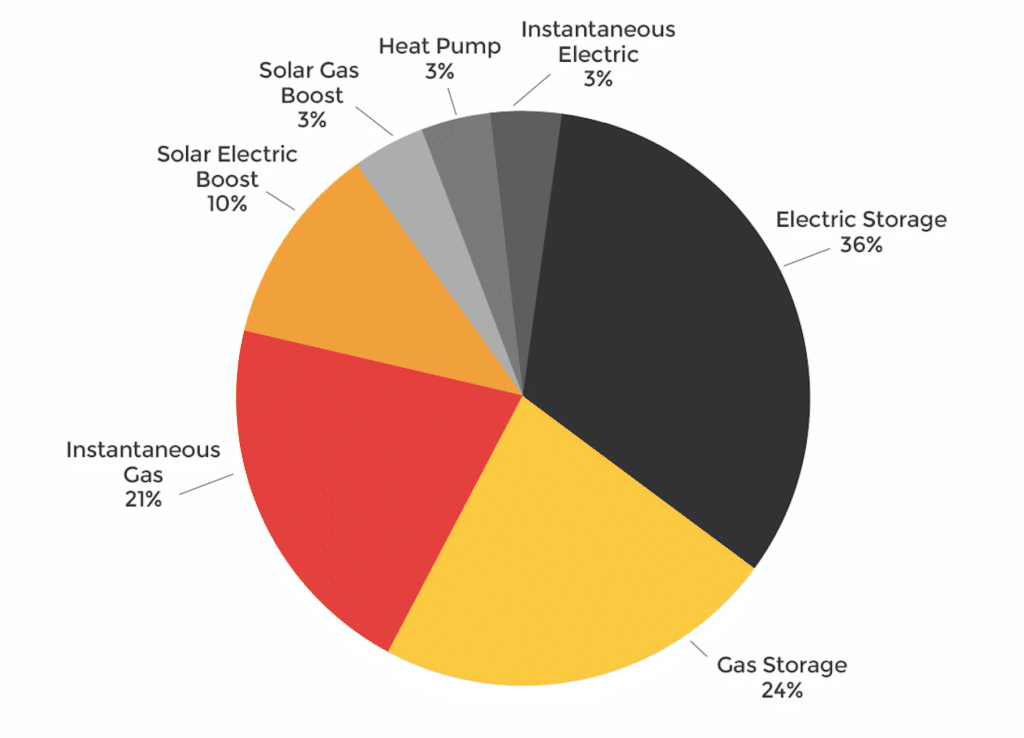

Choosing a right Gas hot water system for your property can be confusing so here is a transparent guide. The gas storage type of hot water system is very popular in the Perth metropolitan area dues to their low supply and installation costs and the availability of cheap natural gas throughout Perth. These units hold a volume of water inside a storage tank, periodically activating the gas burner to keep the water inside at a consistent set temperature. You will normally find these units outside at the side or back of a house but sometimes can also be found as special indoor units that are flued to the outside to allow exhaust gas the escape safely outside.

Factors to consider when choosing a unit are gas type, tank size, recovery time and efficiency In Perth.

Gas type is the fuel gas that the unit will run on. Natural gas (NG) or liquid petroleum gas (LPG) are the two commonly available for properties in Western Australia.

Tank size refers to the volume of water the tank can hold and heat the most common sizes being 90L for small one bathroom flats, 135L and 170L for family homes.

Recovery time refers to the time taken to heat up the water that has been used. Lower recovery time units can produce hot water more quickly making it less likely to run out of hot water during heavy periods of use.

Efficiency is the amount of gas required to heat the water, the more efficient the unit the less gas is consumed to heat the water. Higher efficiency units are designed with better heat transfer and insulation in mind.

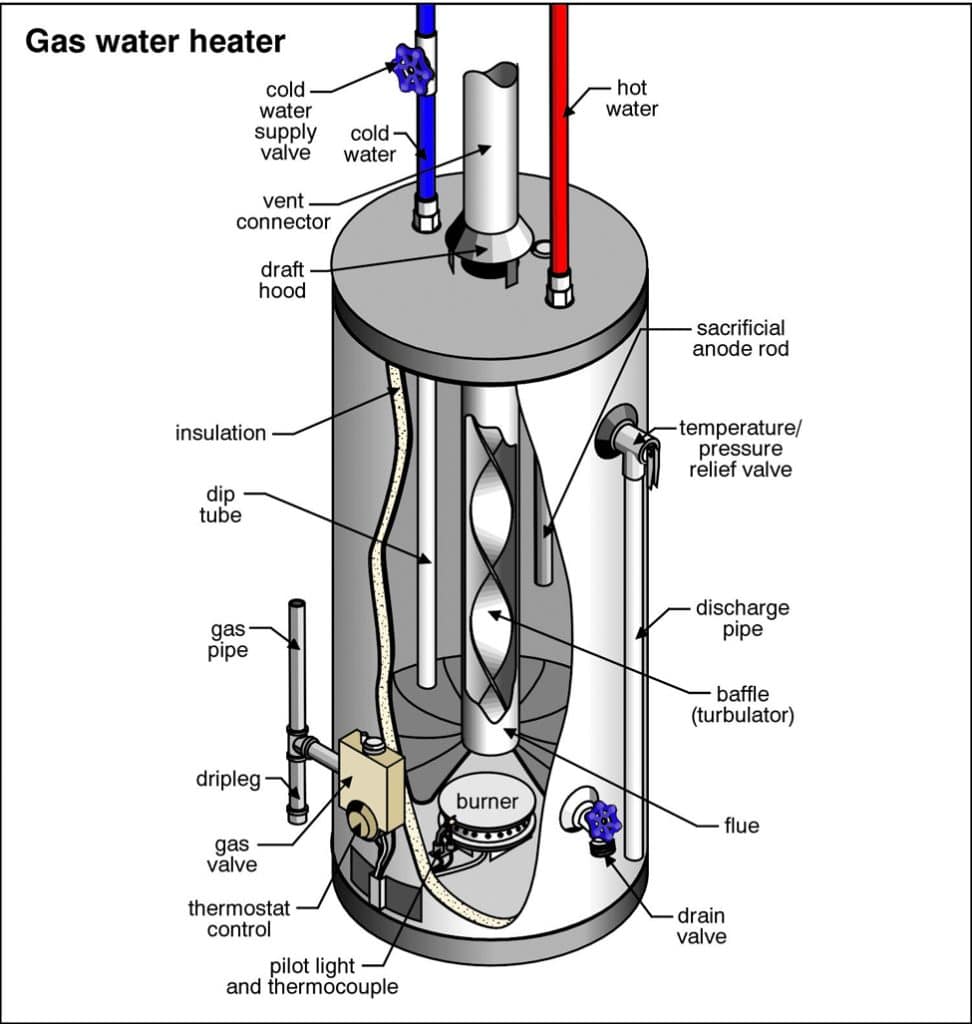

Tanks are normally constructed of steel with a glass enamel lining inside to prevent corrosion of the steel. The tank is insulated and contained in a sheet metal skin. A gas controller and burner is located below the tank and heats from the bottom upwards. A flue is located on the top or front of the unit to vent exhaust gas away from the burner.

Fuel gas types for storage units

Natural Gas (NG) is found all over Perth urban and suburban areas, this gas is supplied from the gas network operators main pipe in the street supplying as much gas as you need. The gas is metered to your property and the gas supplier bills you accordingly. The gas network is ever expanding as the Perth urban sprawl continues.

Liquid Petroleum Gas (LPG) is often found in the Perth hills and surrounding semi-rural and rural areas where the gas network has not yet reached. The gas is delivered in bottles by suppliers to homes and can also be trucked and pumped into larger onsite storage tanks for commercial and industrial customers.

Energy Efficiency

Gas storage water heaters generally rank fairly low on the efficiency scale compared to other types of water heater. The gas efficiency ranges from 3 to 5 stars as rated by the Australian Gas Association.

Advantages of gas storage hot water systems

· Models available to suit different budgets.

· Low to Moderate cost of the unit.

· Low to Moderate cost of installation.

· Various sizes available.

· Gas is cheap and widely available.

· Works without power.

Disadvantages of gas storage hot water systems

· Low to Moderate gas efficiency. Moderate running cost.

· Moderate to high maintenance cost. Major service is recommended every 5 years.

· Large footprint takes up a moderate amount of space.

Choosing a gas Storage unit

Things to consider before choosing a unit:

· Makes and model, check product reviews and reputations to see if it’s right for you.

· Warranty offering and after sales service availability.

· Size required for the property and number of people in the house.

· Gas type available to the property.

· Location available to install the unit.

· Are other types of hot water systems available?

· Cost of the supply and install.

· Budgeting for gas/water consumption and future maintenance.

Generally, the most efficient systems are more expensive to buy but will save on running costs in the future.

Life expectancy of gas storage hot water systems

10 – 15 years is the normal life expectancy for a gas storage water heater in Western Australia. Factors such as water quality and frequency of maintenance will affect the lifespan of a water heater, Clean clear water and frequent maintenance can extend the life of a water heater considerably.

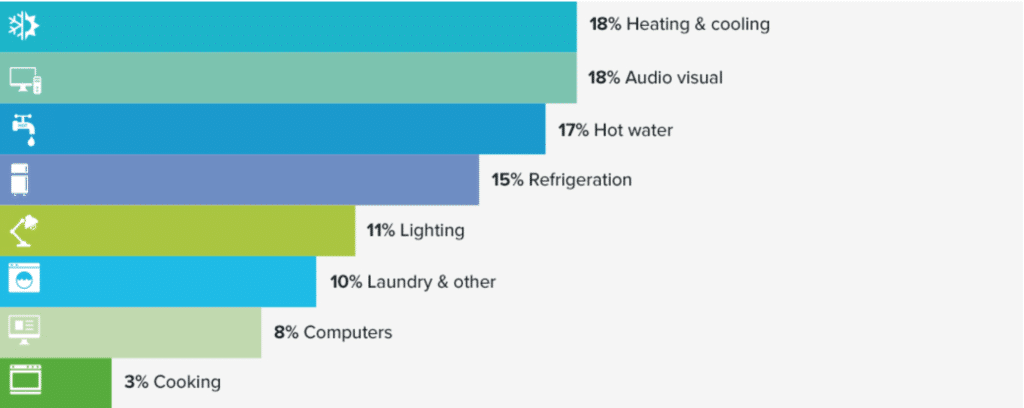

Average household gas hot water usage Perth

Common Faults found on gas storage hot water systems

Common faults found with the gas storage water heaters are:

· Pilot light being extinguished by wind.

· Gas controller component failure.

· Water valve failure and corrosion.

· Pressure relief and Pressure temperature relief valve failure/blockage.

· Tempering valve failure.

· Water pipe blockage.

These faults are often easily identified and fixed by professional plumbers and gas fitters.

The critical failure mode of a gas storage hot water system

The gas storage water heaters main failure mode is when the steal tank is overcome by corrosion and/or pressure and ruptures causing a water leak inside the heater, this is a sign that the heater has come to the end of its serviceable life. A compromised tank is not repairable as it means that the corrosion is spreading around the inside of the tank. Some manufacturers will replace the tank whilst under the warranty period, this, however, is not recommended for units outside their warranty period as it is normally cheaper to replace the whole unit.

Safety surrounding gas storage water heaters

Heating water and fuel gas are two elements that if not used and controlled properly can cause catastrophic damage to persons and property. A tank containing water that is heated uncontrolled can build up pressure before exploding, liquid water will expand 1600 times when turning into water vapor meaning a tank holding liquid water will expand 1600 its volume to release the pressure built up.

The dangers of fuel gas are widely known, the gas itself is flammable and potentially explosive in the right concentration with air. Gas can also displace air in rooms and closed spaces causing asphyxiation. If exhaust gas is not vented away from the unit it can cause the air to be replaced with exhaust gas which will cause the production of carbon monoxide a colorless, tasteless and odorless deadly gas. Ensure that all lighting instructions are followed to avoid burns.

For this reason gas storage water heaters have many safety fail safes to ensure the safe operation of the unit. These are the gas controls and pressure relief devices.

The gas controller is designed to safely active and deactivate the main burner to ensure a consistent temperature inside the water tank it is designed to cut out the main burner when the desired temperature is reached, it will also detect the presence of a pilot flame and only activate the burner if the pilot flame is lit, this stops the buildup of fuel gas inside the unit.

Pressure and temperature relief valves are designed to release any buildup of excess pressure inside of the water tank, they will also active if the water inside the tank reaches a temperature above 99ºC preventing the tanks from reaching a critical pressure inside.

Burns and scolding are also a safety concern, it is required by law that the temperature supplied to showers, baths and basins be regulated to prevent injury.

Bacterial growth is of concern in storage type water heaters, to prevent the growth inside of the tank the controller temperature must be set above 60ºC.

Always use the services of a properly qualified and licensed professional plumber and/or gasfitter for the maintenance and installation of you gas hot water system to ensure your safety.

Regular ‘do it yourself’ checks for gas storage hot water systems

To maximize the life of a gas storage hot water system there are some simple monthly checks you can do yourself.

1. Keep the area clear

– Ensure the area around the unit is clear, give it at least half a meter of space.

– Keep any flammable or combustible materials well away from the unit.

– Ensure plant, tree and weed growth is kept away from the unit.

2. Check the valves

– Check the water isolation valve turns and works.

– Pull the relief valve levers to active and flush out both relief valves. Be aware the water that comes out may be boiling hot. If the valve is blocked or won’t stop running seek the help of a plumber.

3. Check the temperature

-Check the temperature that come out of the tap inside, is it a good consistent temperature?

– Check the setting of the burner control, the ideal number is between 5 and 6.5.

4. Get to know your hot water system

– Read and regularly revise the operating instructions for you system

– Get familiar with the relighting procedure found in the instructions, if you understand the steps practice them to prepare for if the pilot light gets blown out by strong wind..

If you have concerns or queries get in contact with your plumber of the manufacturer of the unit.

Major service for gas storage units.

Manufactures recommend a major service be carried out on your gas storage water heater by a qualified plumber, gasfitter or service technician, every five years to ensure long life, safe operation, efficient running and warranty continuation. The checks and requirements that will be carried out are as follows.

· Replacement of the sacrificial anode inside the tank.

· Replacement of the tempering valve.

· Replacement of the pressure (cold) relief valve.

· Replacement of the pressure-temperature (hot) relief valve.

· Flushing out sediment from the bottom of the storage tank.

· Testing the operation of the water and gas isolation valves.

· Testing the operation of the gas control system.

· Checking the security of the wall mounts.

· Checking the sturdiness of the base.

· Checking for signs of corrosion and rust.

· Commissioning of the unit.

Installation checks done by the installer

During the installation of the gas storage hot water system the installer will perform the following checks before starting:

· A gas tightness test of the existing gas pipework to ensure there are no existing leaks before starting work.

· Location check to ensure the location of the unit it suitable and compliant within the regulations. Making sure it isn’t too close to windows, door, ventilation, internal/external wall corners and combustible materials.

· Check the new unit condition when opening the packaging, report any noticeable and obvious problems found (such as damage or missing parts) to the supplier before installation.

After the installation is complete the installer will check:

· Water valves and pipework for leaks.

· Gas valves and pipework for leaks

· Test the operation of the unit.

· Check the water temperature inside the unit and at the taps inside the house.

Getting maximum value out of your install

To get the most value out of your install ask your installer whether you are getting the following included for the price:

· Are new valves and pipework with your new hot water system?

· Will the installer dispose of the rubbish and old unit off site?

· Will the water pipes and valves thermally insulated as required?

· Do they handle warranty and after sales service?

After the install is complete ensure the installer gives you all the documentation and compliance certificates, also get them to show you the new unit and how to operate it.

Our opinions on brands

Rheem

An established name in Australian hot water since 1936. We have found the Rheem branded gas storage units to be some of the longest lasting and well built units. We often come across Rheem 135L/170L storage units that are 20 plus years old and have never been serviced. The Rheem plus 5 star units and Rheem Stellar are a high efficiency gas storage unit that is popular with builders. After sales service is readily available through Rheem service department for their products. Our experience with Rheem has always been positive.

Vulcan

Made By Rheem, The Vulcan brand gas storage units are equally as tough as the Rheem. Again we find they often last 20 plus years. We highly recommend these as a cheaper alternative to a Rheem 135L/170L 4 star unit. Aftersales provided by Rheem through there service department. Our experience with Vulcan has always been positive.

Thermann

Owned and provided by the plumbing supplier Reece, Thermann is relatively new to the market. They provide a solidly built 135L/170L Gas storage unit. The units are great for those looking for a low cost unit to replace their old 135L/170L. They are yet to prove themselves against the test of time. After sales is handled by Reece Australia wide. Our experiences so far with Thermann has been positive.

Rinnai

While Rinnai is a market leader for continuous flow hot water systems they are relatively new to the gas storage market. We haven’t personally dealt with these storage units to we can’t comment on their construction or life span however initial customer reviews found online are not promising. They are also yet to prove themselves against the test of time.

Dux

An example of a brand in a solo race to the bottom. Once a reliable brand; the units today are built cheap. Our experience with this brand had been horrible. We have witnessed dozens of their storage units catch fire after 2 years causing property damage and risk to lives. The after sales is contracted out to big third party companies that despise the DUX brand and will happily recommend another brand. It is our opinion that this brand is not to be trusted and should be avoided where possible, we will often refuse to install this brand when a client has purchased it without advice.

Compliance in Western Australia

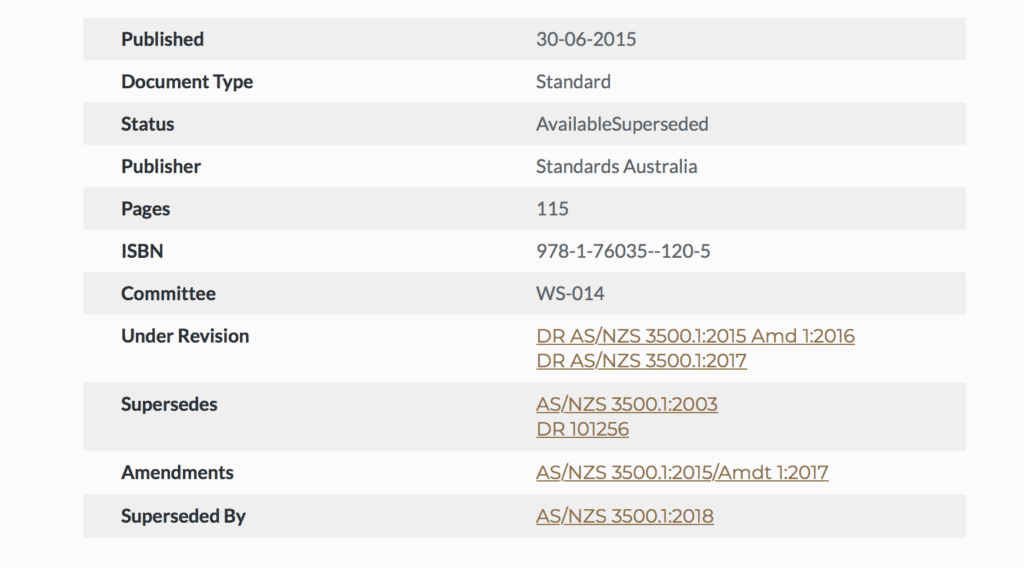

All plumbing in Western Australia work must be carried out by a WA licensed plumber in accordance with Australian standards AS3500. A plumbing compliance certificate will be submitted by the plumbing contractor to the state plumbing authority and a copy given to the customer.

All gas work in Western Australia must be carried out by a WA licensed gas fitter in accordance with Australian Standards AS5601. A gas compliance certificate will be submitted by the gas fitter to the gas authority and a copy given to the customer.

Compliant work ensures safety, warranty, efficiency and long service life of the unit Perth wa.